- Low Strain Integrity Test (Seismic Test)

- Side Echo Test

- Single Shock End Test

- Cross Hole Sonic Logging Test

Low Strain Integrity Test (Seismic Test)

Low strain integrity test is one of the methods for assessing the condition of piles or shafts. It is cost effective and not very time consuming. This method is covered under ASTM D5882 Standard Test Method for Low Strain Integrity Testing of Piles. The test is based on wave propagation theory. The name "low strain integrity test" stems from the fact that when a light impact is applied to a pile it produces a low strain. The impact produces a compression wave that travels down the pile at a constant wave speed. Changes in cross sectional area - such as a reduction in diameter - or material - such as a void in concrete - produce wave reflections. This procedure is performed with a hand held hammer to generate an impact, an accelerometer or geophone placed on top of the pile to be tested to measure the response to the hammer impact, and a data acquisition and interpretation electronic instrument. Moreover, This Scope of work in low Strain integrity test has been certified according to ISO9001:2015 standard which is the first and only testing company in Thailand that is certified in this section.

Side Echo Test

The Side Echo Test is modified method from normal sonic echo test (seismic test). The purpose of this testing is applied to evaluation the integrity condition and length of the pile foundation when foundation tops are not accessible. Due to the foundation top cannot accessible, the excavation beside the foundation pile is required until the pile side is accessible. The transfer block (steel block 500 ×500×250 mm.) shall be attached to the side of test pile by expansion bolt. This block is used to transfer the compression wave down to the pile. Before testing the tri-axial accelerometer geophone shall be attached beside the pile at approximate 0.15-0.20 cm. below the transfer block. After that the transfer block is struck by the hand held hammer on the vertical direction. The movement of the pile, caused by hammer impact stress wave and subsequent reflection is measured by the above mention sensitive accelerometer. The acceleration signal is converted to velocity and presented on screen as function of time. All result are stored for use in reports.

cc

cc

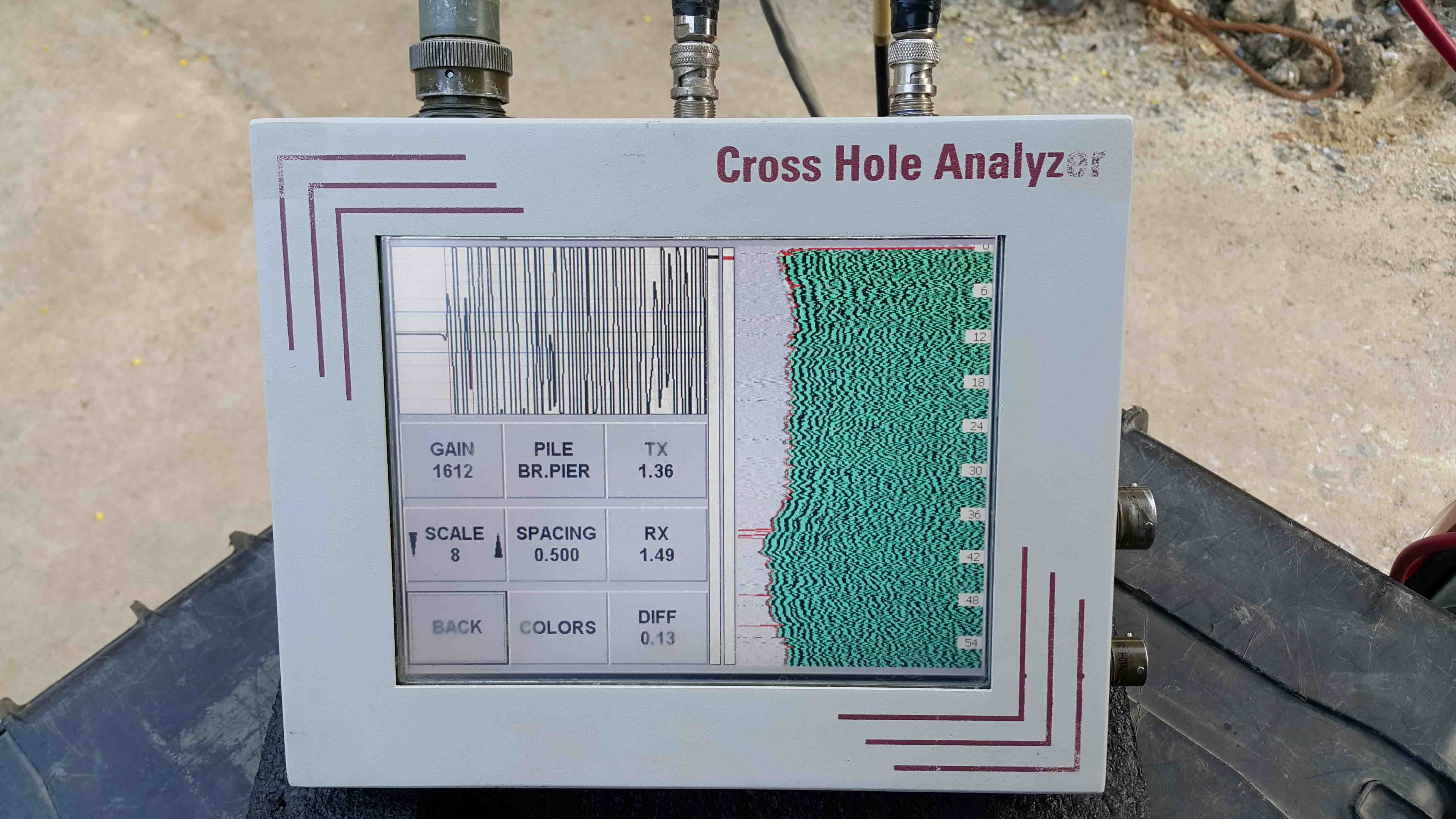

Cross Hole Sonic Logging Test

Cross hole sonic logging is a method to verify the structural integrity of drilled shafts and other concrete piles. This method is covered under ASTM D6760. The method is considered to be more accurate than sonic echo testing in the determination of structural soundness of concrete within the drilled shaft inside the rebar cage. This method provides little indication of concrete soundness outside the cage. Cross Hole Acoustical Testing normally requires steel (preferred) or PVC access tubes installed in the drilled shaft and tied to the rebar cage. Before the rebar cage is placed in the hole, the access tubes are attached to the interior of the rebar cage. The cage is then lowered into the hole and the concrete is placed. Steel tubes are preferred over PVC tubes because studies have shown that PVC tubes tend to de-bond from the concrete due to the heat of hydration process of concrete.

The tubes are filled with water as an intermediate medium. After curing for 7-14 days, a sound source and receiver are lowered, maintaining a consistent elevation between source and sensor. A signal generator generates a sonic pulse from the emitter which is recorded by the sensor. Relative energy, waveform and differential time are recorded, and logged. This procedure is repeated at regular intervals throughout the pile and then mapped. By comparing the graphs from the various combinations of access tubes, a qualitative idea of the structural soundness of the concrete throughout the pile can be gleaned.

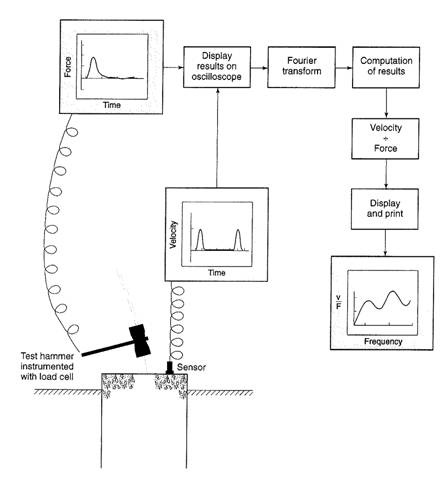

Single Shock End Test

Single Shock End Test is the advanced method compared with the Conventional Low strain Seismic Test for testing the integrity of the pile foundation. In a Conventional seismic test, the basic concept in analyzing the result is based on Time-Based Techniques. The interpretation result displays in the relation between pile head velocity and depth of pile structure and the impact pulse is generated by Non-Instrument hammer. While in the Shock Testing the impact pulse stress wave is generated by using Instrument hammer which can record the signal in both of pile head velocity and force versus depth.

Frequency response method use modern computational techniques to analyze the composite wave from. The information obtained by using Shock Testing is shown in list below:-

1.Impact quality and concrete quality near pile top

2. Pile defect along the investigated length

3. Approximated pile length (if possible)

4. Characteristic mobility (M) and Pile head dynamic Stiffness (E’)

Cross Hole Sonic Logging Test

Cross hole sonic logging is a method to verify the structural integrity of drilled shafts and other concrete piles. This method is covered under ASTM D6760. The method is considered to be more accurate than sonic echo testing in the determination of structural soundness of concrete within the drilled shaft inside the rebar cage. This method provides little indication of concrete soundness outside the cage. Cross Hole Acoustical Testing normally requires steel (preferred) or PVC access tubes installed in the drilled shaft and tied to the rebar cage. Before the rebar cage is placed in the hole, the access tubes are attached to the interior of the rebar cage. The cage is then lowered into the hole and the concrete is placed. Steel tubes are preferred over PVC tubes because studies have shown that PVC tubes tend to de-bond from the concrete due to the heat of hydration process of concrete.

The tubes are filled with water as an intermediate medium. After curing for 7-14 days, a sound source and receiver are lowered, maintaining a consistent elevation between source and sensor. A signal generator generates a sonic pulse from the emitter which is recorded by the sensor. Relative energy, waveform and differential time are recorded, and logged. This procedure is repeated at regular intervals throughout the pile and then mapped. By comparing the graphs from the various combinations of access tubes, a qualitative idea of the structural soundness of the concrete throughout the pile can be gleaned.